Department of Physical Chemistry

Nanostructured Model Catalysts

Department of Physical Chemistry

Nanostructured Model Catalysts

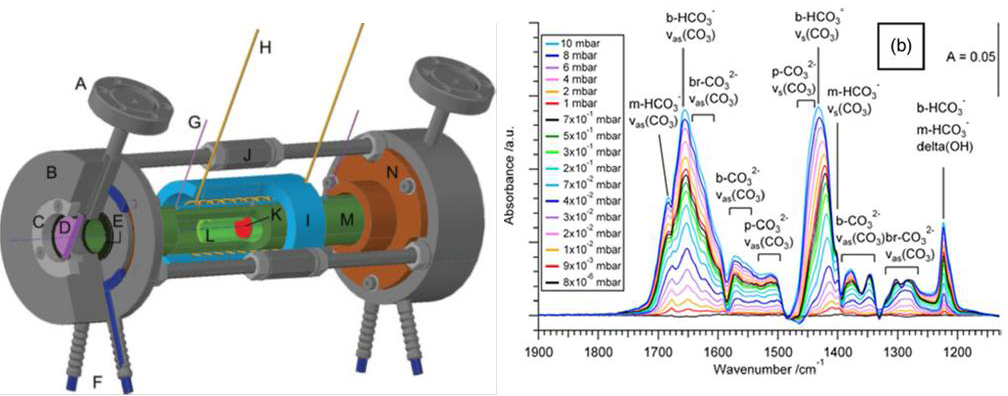

Part of our research is focused upon the development or adjustment of scientific apparatus, which better serve the needs of our research and to answer dedicated and specific questions arising during our studies. Recent examples include the development of an ultra-dry operando reactor cell for FT-IR spectroscopy, that is capable of operating at 1000°C – collection of spectra included. Using this dedicated setup, we are able to operando – in the working state – follow the adsorption and reaction of molecules at surfaces under extreme conditions: high pressures of reactive gases and high temperatures. These are e.g. typical working conditions of solid-oxide fuel cells (SOFC). In Figure 1, a 3D scaled drawing of the reactor cell is shown (left), alongside pressure-dependent IR spectra of surface carbonates following adsorption of CO2.

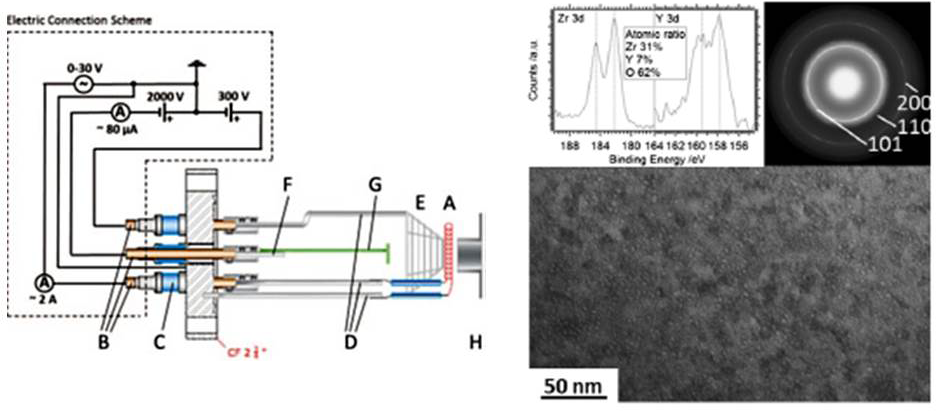

In a second project, development of a flexible sputter-gun for oxidic and metallic targets was put forward. This apparatus has been developed on the one hand to overcome the limitations of other deposition techniques, such as thermal evaporation. The latter is highly unfavorable for refractory materials with a low vapor pressure, e.g. Zr metal or ZrO2, which are both in our current research focus. On the other hand, due to its compact construction, it can be easily mounted to UHV chambers to deposit fractions of a monolayer of oxide or metals or to HV chambers to grow nm and µm-thick films. In this respect, different classes of materials are preparation-wise easily accessible. Figure 2 highlights a schematic drawing of the gun (left), as well as structural and compositional characterization of a 8 at% - YSZ thin film (25 nm) by TEM and XPS.

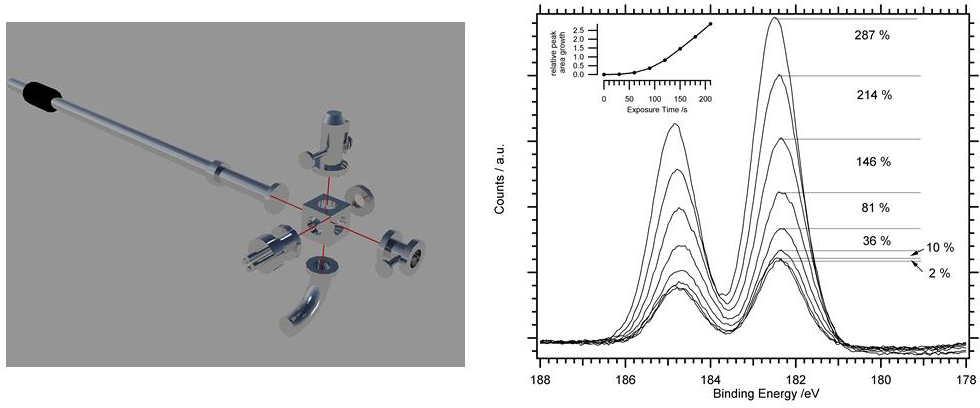

Thirdly, our group recently constructed a flexible chemical vapour deposition source, whose particular advantage is also the high flexibility – it can be attached to conventional UHV chambers as well as to e.g. synchrotron facilities. This makes the comparison of data obtained from different systems highly comparable and reliable. The right panel in the Figure 3 shows an explosion diagram of the cell (left), alongside the evolution of the Zr 3d peak during prolonged exposure of the sample surface to Zr organyl species.